Vapor Processing: Evaporation, ALD, and VPI

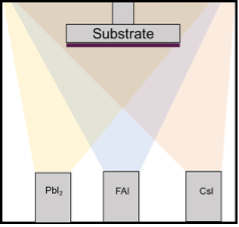

We use thermal co-evaporation and flash evaporation to deposit halide perovskite thin films with different compositions such as MAPbI3, FAPbI3, and CsxFA(1-x)PbI3 by carefully controlling the evaporation parameters. These methods also allow for shorter deposition times, which is of interest to industry.

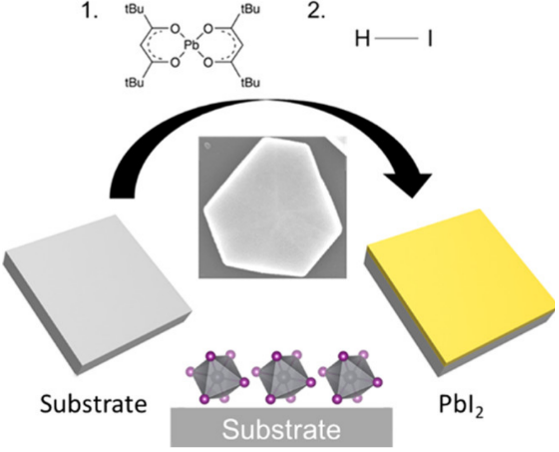

We are developing atomic layer deposition (ALD), which will allow the formation of uniform halide perovskite layers with angstrom-level thickness control. This technique is being implemented for the fabrication of perovskite microcavities that show strong light-matter interactions, and the deposition of 2D perovskite to reduce interface recombination in perovskite solar cells.

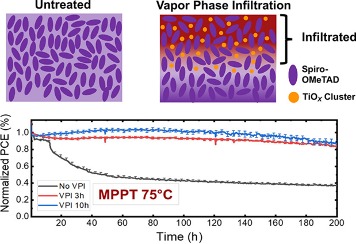

We are developing vapor phase infiltration (VPI) in collaboration with the group of Professor Mark Losego to improve the stability of organic materials used in organic and hybrid devices by incorporating metal oxide clusters. As an example, we have shown that infiltration of TiO2 in a spiro-OMeTAD layer leads to an improvement in the stability of perovskite solar cells at high temperatures (75°C).

Details and References

Group Members: Jack Martin Carlo

Perovskite solar cells (PSCs) have achieved a record efficiency of 25.6% by using spin coating for the deposition of most of the layers involved. Careful control of the phase purity, morphology, and thus optoelectronic properties of the layers has been crucial to achieve these results. However, there are many drawbacks of the spin coating deposition approach, such as low throughput, extensive amounts of toxic solvents, low quality of films near the edges of the substrates, the presence of large defects in the film, and solvent orthogonality. These drawbacks translate into roadblocks for thin film processing in large scale. We study the deposition of energy materials by different vacuum-based deposition techniques to address these concerns.